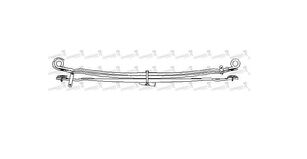

Coil Spring for truck

PDF

Share

Facebook

WhatsApp

Viber

Telegram

Interested in the ad?

1/7

PDF

Share

Facebook

WhatsApp

Viber

Telegram

Price:

on request

Ask for price

Contact the seller

Type:

coil spring

Location:

United Arab Emirates Ajman11569 km from you

United Arab Emirates Ajman11569 km from you

Placed on:

Jan 21, 2025

Autoline ID:

LW41519

Condition

Condition:

new

Important

This offer is for guidance only. Please request more precise information from the seller.

Purchase tips

Seller's contacts

Subscribe to seller

Sabeesh

Languages:

English, Arabic

Priority communication method

Send message

Seller's contacts

AUTO ZONE ARMOR & PROCESSING CARS LLC

United Arab Emirates

United Arab Emirates 4.6

37 reviews

Subscribe to seller

+971 50 959...

Show

+971 50 959 3559

+971 6 743...

Show

+971 6 743 3458

Ask the seller

PDF

Share

Facebook

WhatsApp

Viber

Telegram

Selling machinery or vehicles?

You can do it with us!

Similar ads

€61.24

≈ $63.65

≈ ZAR 1,186

228785820

Contact the seller

Price on request

Contact the seller

Price on request

Contact the seller

Price on request

A 960 310 07 55 / 75 961 15

Contact the seller

Price on request

Contact the seller

€82.64

≈ $85.89

≈ ZAR 1,600

diesel

Contact the seller

€37.19

≈ $38.65

≈ ZAR 720

diesel

Contact the seller

€578.10

PLN 2,435

≈ $600.80

33872000 9443200702

Contact the seller

€423.30

PLN 1,784

≈ $440

7485139438

Contact the seller

€496.30

PLN 2,091

≈ $515.80

5010130726

Contact the seller

€432.10

PLN 1,820

≈ $449.10

Schomäcker 29412000 O.E. 1700733

Contact the seller

€385.40

PLN 1,624

≈ $400.50

O.E. 1164010

Contact the seller

€321.10

PLN 1,353

≈ $333.80

Schomäcker 29427000 O.E. 1401325

Contact the seller

€578.10

PLN 2,435

≈ $600.80

Schomäcker 29425000 O.E. 1700740

Contact the seller

€627.70

PLN 2,645

≈ $652.40

Schomäcker 29380000 O.E. 1346914

Contact the seller

Dobinson’s™ proudly boast one of the world’s largest range of coil springs including raised height and heavy duty 4wd springs, lowered performance passenger car springs, O.E. replacement springs and heavy duty springs for commercial vehicles.

State of the Art Heat Treatment

Heat treatment is unseen and is the most important steps in the coil spring manufacturing process. Hardening and tempering is completed by an extremely precise electronically controlled furnace to eliminate breakage and sagging.

Formed On Precision Mandrels

Each coil is precisely placed by a programmable logic computer to achieve perfect pitch. This is especially important in manufacturing variable and progressive rate springs.

High Intensity Shot Peening

All Dobinson’s coils are shot peened to give longer life.

Precise End Configurations

Engineered coil ends are designed to fit directly into the original vehicle mounting points without any modification.

Design Technology

Spring Design engineers within Dobinson’s Spring & Suspension™ utilize the latest coil spring design programs to ensure each spring will meet and exceed the design requirements and achieve the maximum working life. These state of the art design programs are crucial when designing variable/progressive rate springs to ensure laden and unlade spring rates are correct to provide the best possible ride comfort and handling.

Powder Coat Finish

A durable powder coat finish provides extreme protection against the elements

Fully Scragged & Load Tested

All coils are scragged 100% to eliminate subsequent spring sag and load tested to ensure that they meet and maintain the required specifications. Dobinson’s also perform spring fatigue testing and spring hardness testing using in-house state of the art testing equipment.

Specifications

Armored level : B6+

COIL SPRINGS

Dobinson’s™ proudly boast one of the world’s largest range of coil springs including raised height and heavy duty 4wd springs, lowered performance passenger car springs, O.E. replacement springs and heavy duty springs for commercial vehicles.

State of the Art Heat Treatment

Heat treatment is unseen and is the most important steps in the coil spring manufacturing process. Hardening and tempering is completed by an extremely precise electronically controlled furnace to eliminate breakage and sagging.

Formed On Precision Mandrels

Each coil is precisely placed by a programmable logic computer to achieve perfect pitch. This is especially important in manufacturing variable and progressive rate springs.

High Intensity Shot Peening

All Dobinson’s coils are shot peened to give longer life.

Precise End Configurations

Engineered coil ends are designed to fit directly into the original vehicle mounting points without any modification.

Design Technology

Spring Design engineers within Dobinson’s Spring & Suspension™ utilize the latest coil spring design programs to ensure each spring will meet and exceed the design requirements and achieve the maximum working life. These state of the art design programs are crucial when designing variable/progressive rate springs to ensure laden and unlade spring rates are correct to provide the best possible ride comfort and handling.

Powder Coat Finish

A durable powder coat finish provides extreme protection against the elements

Fully Scragged & Load Tested

All coils are scragged 100% to eliminate subsequent spring sag and load tested to ensure that they meet and maintain the required specifications. Dobinson’s also perform spring fatigue testing and spring hardness testing using in-house state of the art testing equipment.